On the May 16 took place a workshop organized by “Gasprom Transgas Ekatherinburg” Ltd with the participation of the representatives of the Moscow

On the May 16 took place a workshop organized by “Gasprom Transgas Ekatherinburg” Ltd with the participation of the representatives of the Moscow

OJSC “Gasprom” and IHTE UB RAS scientists. The possibilities of the import-substituting equipment pilot testing on the basis of the “Gasprom” sub-company in Ekaterinburg, with which the Institute collaborates several years, were discussed. The present workshop was carried out on the territory of the gas-distributing station “Gasprom Transgas Ekatherinburg”, which operates Novo Sverdlovsk TPP. Here the IHTE developed power sets and other innovation technologies are tested.

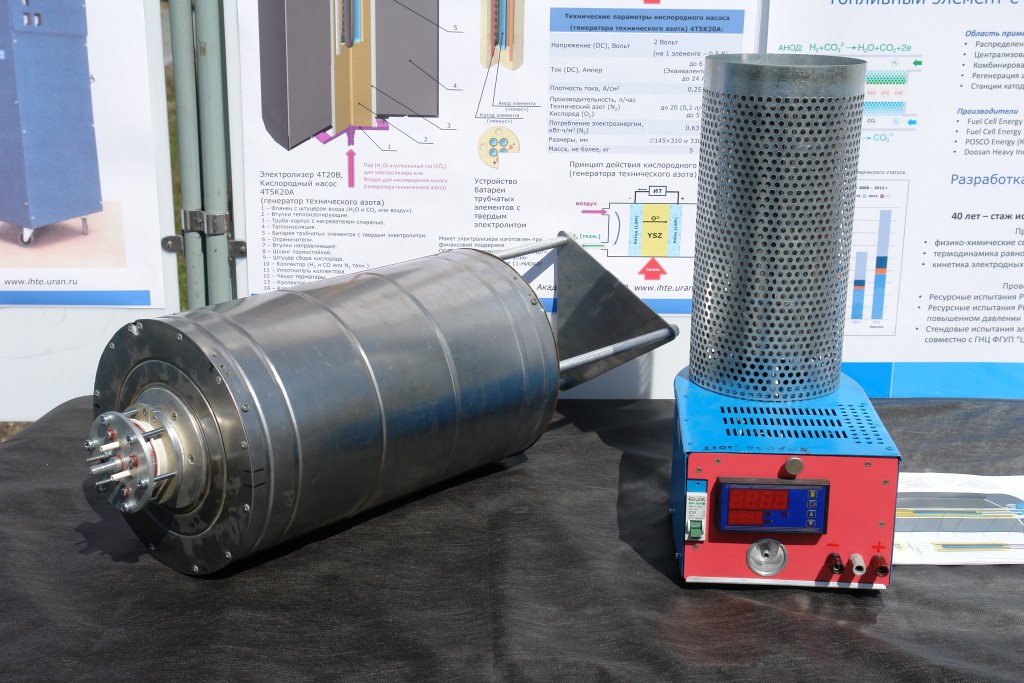

Firstly the scientists demonstrated experimental samples of the “brand mark” technology — a solid oxide fuel cells (SOFC) based power set.

The advantages of the electrochemical generators based on SOFC are widely known: high efficiency (only electric current efficiency is above 30%), simple and reliable construction, small size and weight, quiet operation and no emission. The main advantage of the set is the ability to consume either natural gas: methane, butane, propane, oil, diesel fuel, carbon, alcohol as well as wood, peat, chippings or even argi-production wastes.

SOFC based power sets are the alternative to diesel and oil generators. A diesel engine, which is made of many details and works 24 hours a day, requires a constant lubrication and trimensual technical treatment. If such an engine is in a remote area, the fuel feed may be more expensive than the cost of the fuel. The Gasprom specialists are highly interested in the sets, which use natural gas, because all Gasprom objects are supported with gas.

Power sets, developed by Ural electrochemists are differentiated by an original design of tubular elements and stacks. This is an optimal variant for small constructions, the difference from the planar construction plates is that a tubular fuel cell starts operating faster and its operation life is longer.

Two test benches with the capacities of 1.5kW and 220 W were demonstrated at the workshop. The autonomous power set with the capacity of 1.5 kW is made as the supply for the cathode protection of main gas lines and underground structures. It may be used as reserve and constant electric current and heat sources at control stations, for housing objects in remote regions, at mobile communication message relay points.

The capacity of the second set is significantly smaller – 220 W. This is a huge advantage, because there is a deficit in such generators, when small capacity is required. Today foreign thermoelectric converters are used. They are awkwardly shaped and weight about 1000 kg, but the main disadvantage is low efficiency not exceeding 4 %. In addition they are of the same price as SOFC based power sets.

During the workshop the Gasprom representatives understood that the IHTE developed technology allows producing power sets of different capacity with the range required by the customer – from 200 W to 5 kW.

Both electrochemical devices were developed and produced in cooperation with the Rosatom company ‘TVEL”, Electrochemical converters plant and “UralIntech” company with financial support of “Gasprom Transgas Ekatherinburg” Ltd. The power sets are being prepared for interindustry tests.

IHTE scientists also demonstrated the electrolytic cell for hydrogen production from either water vapor or CO, or for syngas production from carbon dioxide and oxygen pump. Capacities of both devices are 20 liters per hour. Oxygen pump is of interest for Gasprom representatives as technical nitrogen generator, but it may be used in medical purposes to obtain chemically pure oxygen.

The samples of thermal chemical current sources (TCCS) also attracted interest. These batteries, which may be kept for 15 years in severe conditions at temperatures from – 50◦ to + 50◦, are extremely useful in remote northern areas. It is small and may be put into the trunk, if accumulator faults thermal chemical current source helps to start the engine.

Gasprom specialists may use reserve batteries TCCS for the emergency sluice valves closure at the main gas lines and engines start at minus temperatures, for welding and cutting metals in emergency and in hard-to-reach spots, for energy supply of lifts and shafts at current break downs and for automatic fire-fighting.

The carbonate fuel cell, reference electrode, anode bed for electrochemical protection of pipelines in slumps and anticorrosion coatings samples were also presented at the workshop. The steel borating technology in molten salts, the technology of thermodiffusion alitizing of steel details, details made of nickel alloys, titanium, copper and the technology of thermodiffusion zincing in power media have been developed in IHTE.

As the IHTE UB RAS director Zaykov Yu.P. noted, the Gasprom specialists search for highly reliable Russian technologies, which may substitute foreign equipment. The scientists are looking forward to a fruitful collaboration with the manufacturers, which allows implementing their developments into innovation technology market.