On September 25, 2019, Aleksandr A.Kataev has successfully defended his Ph.D. thesis on the specialty Technology of electrochemical processes and protection against corrosion. The topic of work was the production of Al-B alloys by the reduction of KBF4 and B2O3 in low-melting cryolite melts. On February 6, 2020, Alexandr has received confirmation from the Higher Attestation Commission on the issuance of the PhD diploma.

The young scientist told about his research, preparation for the defense and shared his future plans:

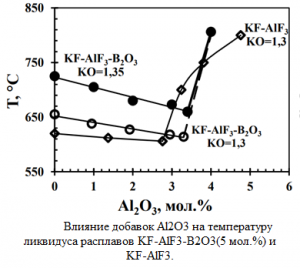

— My thesis is devoted to the study of the physicochemical properties of melts for the production of aluminum boron alloys. I focused specifically on studying the low-melting cryolites. It was interesting to found that they are very good media for obtaining aluminum-boron ligatures. And the development of the technology for obtaining these ligatures became the basis of my dissertation. Along with the study of thermal stability, liquidus temperature, solubility of Al2O3 in boron-containing cryolite melts and determination of their density and electrical conductivity, we, for the first time, as far as I know, revealed the mechanism of interaction of KBF4 and B2O3 with melts based on low-melting potassium cryolite, which was confirmed by multiple laboratory tests.

Andreiy Isakov, the head of the laboratory of Electrocrystallization and High Temperature Galvanotechnics of IHTE, considers my thesis fundamental for a whole area of future work, since the principle, technical and material science solutions and methods of obtaining alumina-boron alloys are “tested” in it. According to Andrey, the “highlight” of the work is that the aluminum alloy is obtained with the use of not the elementary boron itself, but its compounds, which significantly increases the efficiency of the process and excludes additional processing. Following this principle, many methods can be developed for producing aluminum alloys with boron, scandium and many other elements that are capable of dissolving in aluminum under these conditions.

I honestly admit that everything was difficult during the preparation process: to write the text, correctly draw up a huge number of documents and observe all the bureaucratic aspects.

But I am generally lucky in life. I had the best school with the most excellent teachers. I was always surrounded by the most wonderful people, including the head of the laboratory, Olga Yu.Tkacheva. She and Andrey V. Isakov helped me a lot, Alexey Rudenko was always there. Of course, I was supported by Yuri P. Zaikov, my scientific advisor. Special thanks to Nina P. Kulik for invaluable assistance in paperwork and preparation of the work.

My advise to the future dissertation candidates is to be patient and try to react more calmly to any criticism and any suggestions. It all depends only on the candidate himself. The defense itself is not so difficult, the most difficult, in my opinion, is what precedes it.

The immediate plans are to survive the pandemic and continue to work for the good. The aluminum-boron theme continues to be the main in our research and development. Based on the results of the dissertation, a technology for direct aluminum production was proposed, which is protected by a patent for the invention named the Method of obtaining an aluminum-boron master alloy (Yu.P. Zaikov, O.Yu. Tkacheva, A.A. Kataev, M.Yu. Mikryukov, A. V. Suzdaltsev, Yu.M. Shtefanyuk, V.H. Mann)

Our research team hopes that the results obtained will find application in many future projects. For example, we are currently investigating the kinetics of dissolution of aluminum oxide in industrial cryolites. For this, new devices were purchased: METAVAK-K – an oxygen gas analyzer (Granat group of companies) and a unique in Russia high-temperature rheometer FRS 1600 (Anton Paar), which can later be used in work not only with aluminum, but also with silicon, rhenium and other refractory metals.